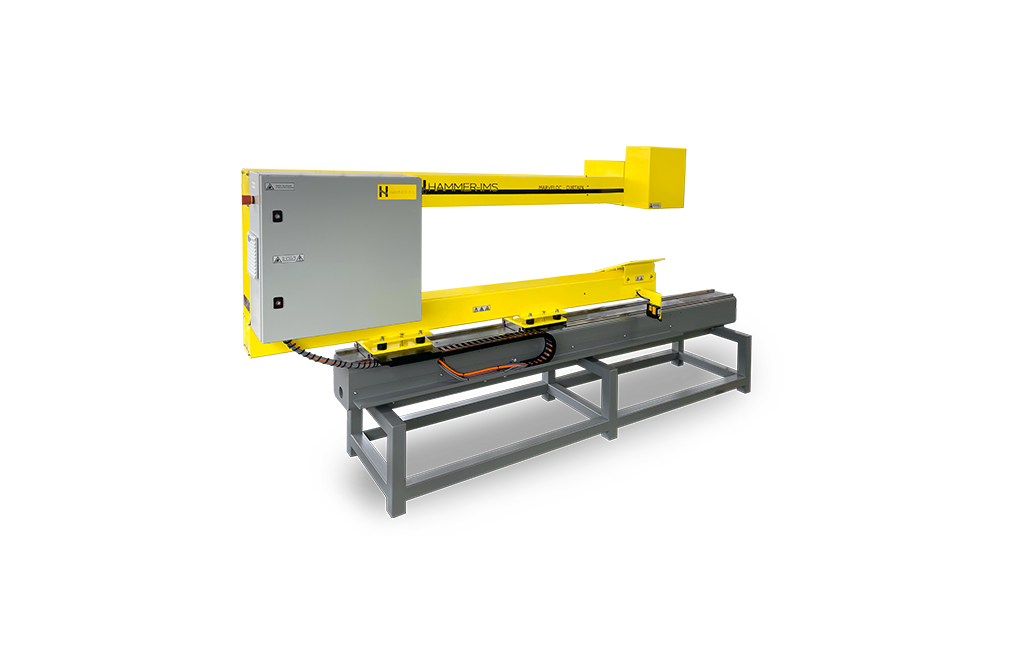

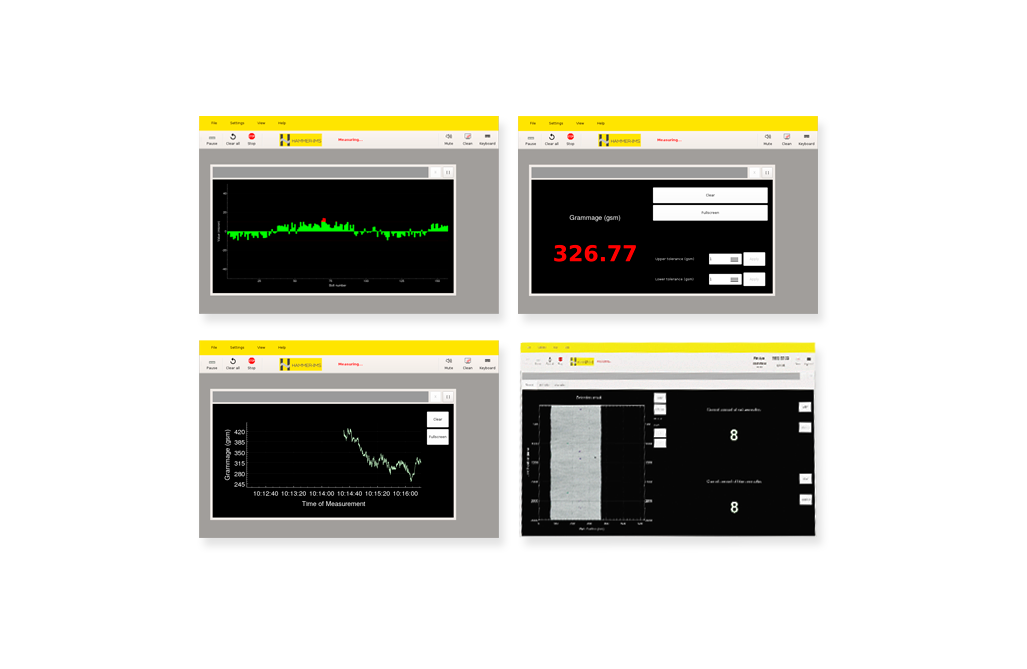

A market where Hammer-IMS is gaining momentum includes the inspection of rubber sheets. Important is that the sheets are produced with uniform material thickness. Flat rubber sheets undergo dedicated inspection of material composition and dimensional quality control, the latter with a Hammer-IMS thickness measurement system, for example. The scanning quality control system can be positioned right after the chilling rolls. It robustly measures the hot, freshly extruded material. The system, including one or more sensors, verifies material thickness caused by variations in the extrusion bank which may slightly shift under varying pressures. The solution enables production supervisors to respond and adjust the extrusion process much faster to keep material thickness steady and avoid wasting base material.

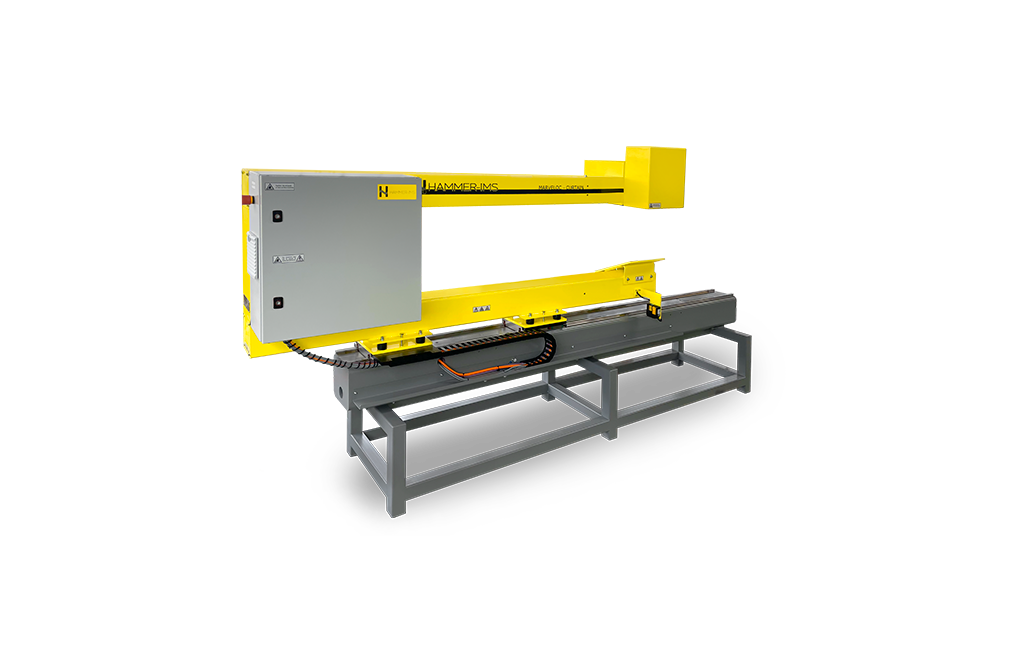

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

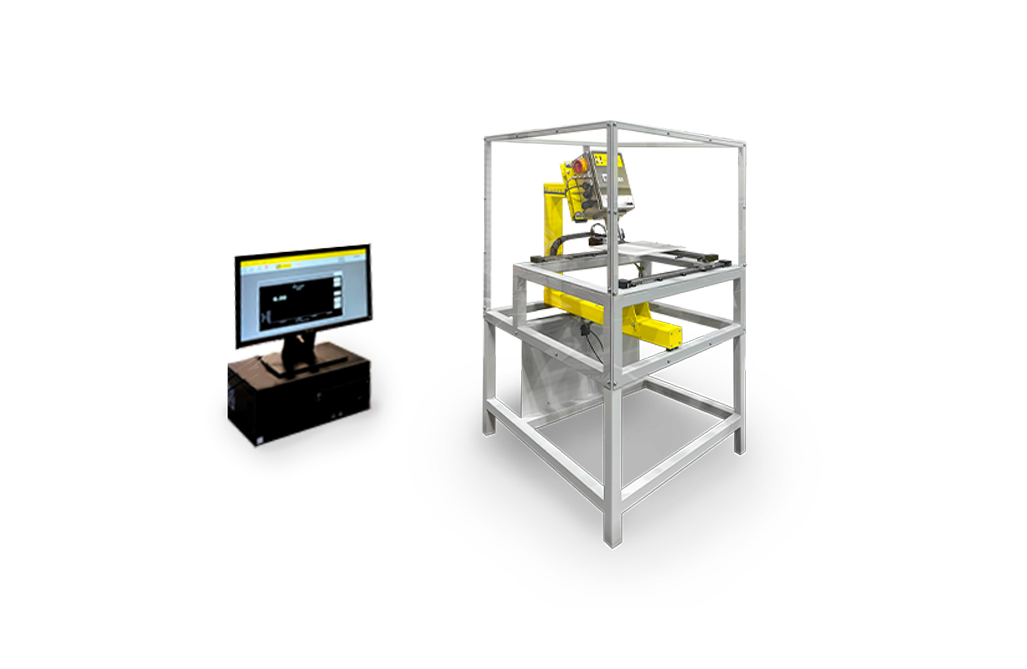

For OEM projects on thickness measuring by machine builders and sensor integrators

Industrial software to connect to PLC's and various information sources

Lab devices, custom or off-the-shelf