Our Software and HMI Technology

Connectivity 3.0 on a rugged industrial platform

The Marveloc featured products of Hammer-IMS are controlled through our Connectivity software. It allows you to control any Marveloc-CURTAIN or Marveloc-CHARIOT systems in a single software environment, regardless whether you are using a single-sensor or a multi-sensor system. The software is easy to use, contains various industry-specific visualizations, and is available pre-installed on a rugged industrial PC or a desktop PC offering a widescreen experience. The software offers a various number of both timestamped and position-based visualizations.

Connectivity 3.0 can be interfaced remotely by means of an embedded TeamViewer installation. This TeamViewer installation enables Hammer-IMS staff to monitor the installation's behavior as part of training and servicing activities.

Hammer-IMS supports a wide range of industry-standard bus protocols. We support integrations based on Modbus TCP/IP, OPC UA or PROFINET for real-time links with existing industrial infrastructure. In this way, the data provided by our measuring systems can be used real-time by existing equipment to optimize the production process in real-time.

PMC felts grammage measurements at Heimbach Group

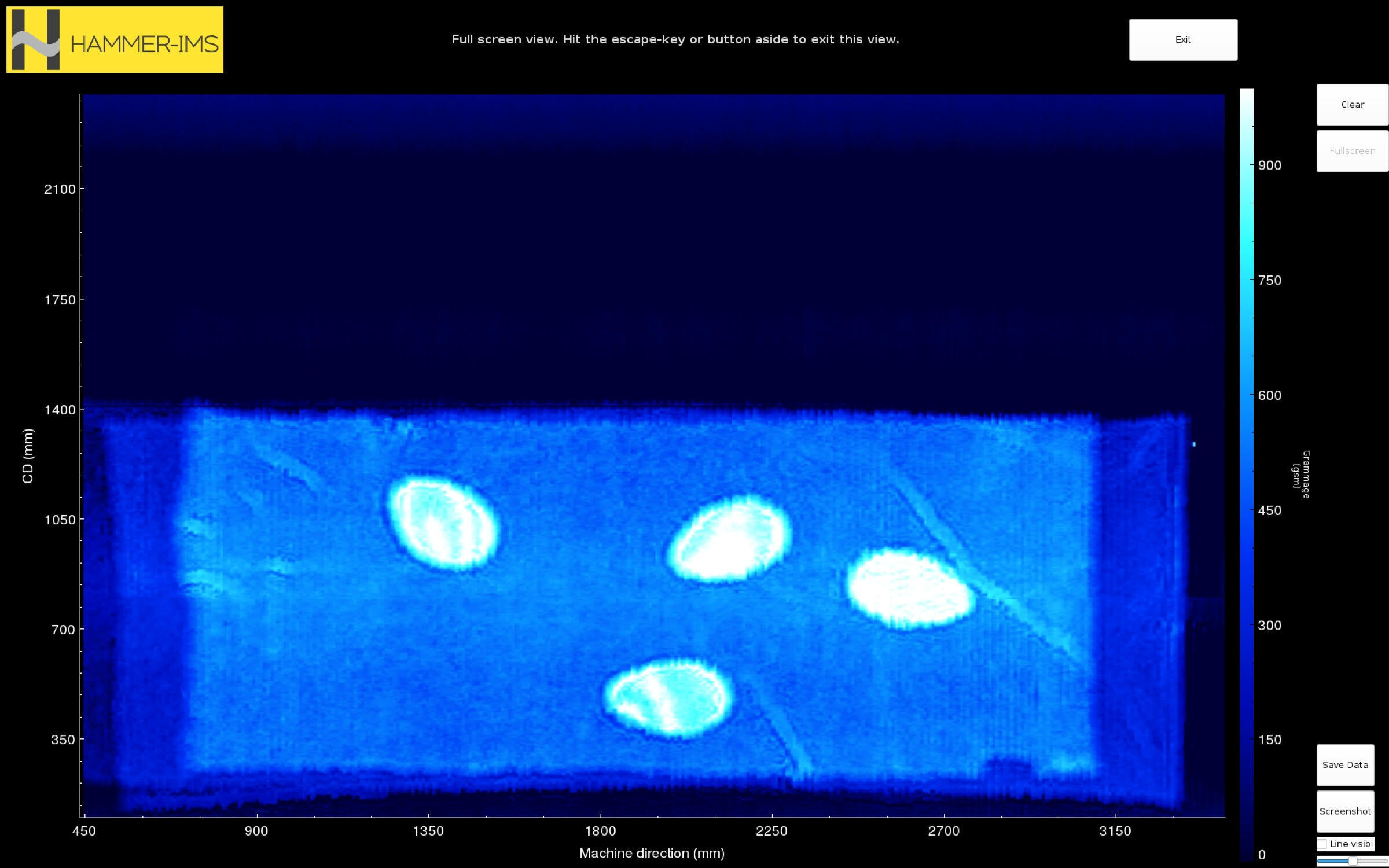

Watch our latest dual scanning system, which serves as an inline project for PMC felts at Heimbach Group (Olten, Switzerland). The automated M-Ray based system for grammage quality control eliminates radioactive sources at what the customer calls the pre-needle loom. We collaborated with Vansichen Linear Technology to fit a nearly 9 meters long steel linear module into a very limited inclined space envelope. This is an example where multiple Hammer-IMS measuring machines are controlled by our Connectivity 3.0 software.

Connectivity 3.0 Video walkthrough

Check out the software walkthrough video. Make sure you enable the sub-titles in the video for a detailed explanation of the shown functionalities!

Some highlights of Connectivity 3.0

Minimal design

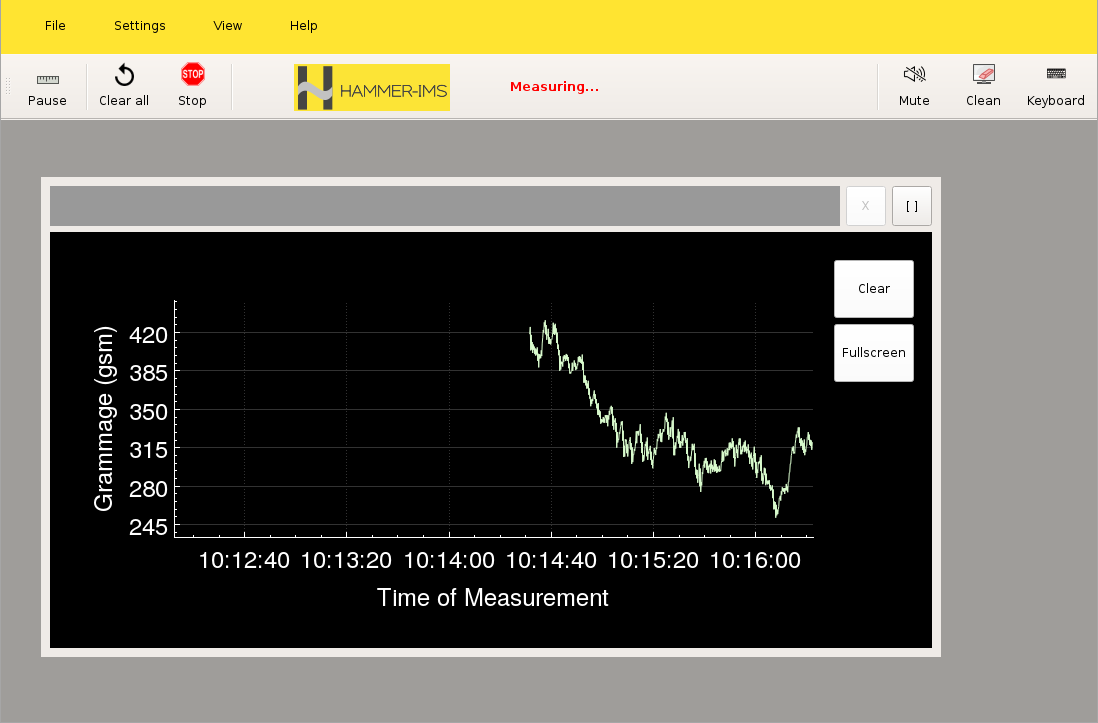

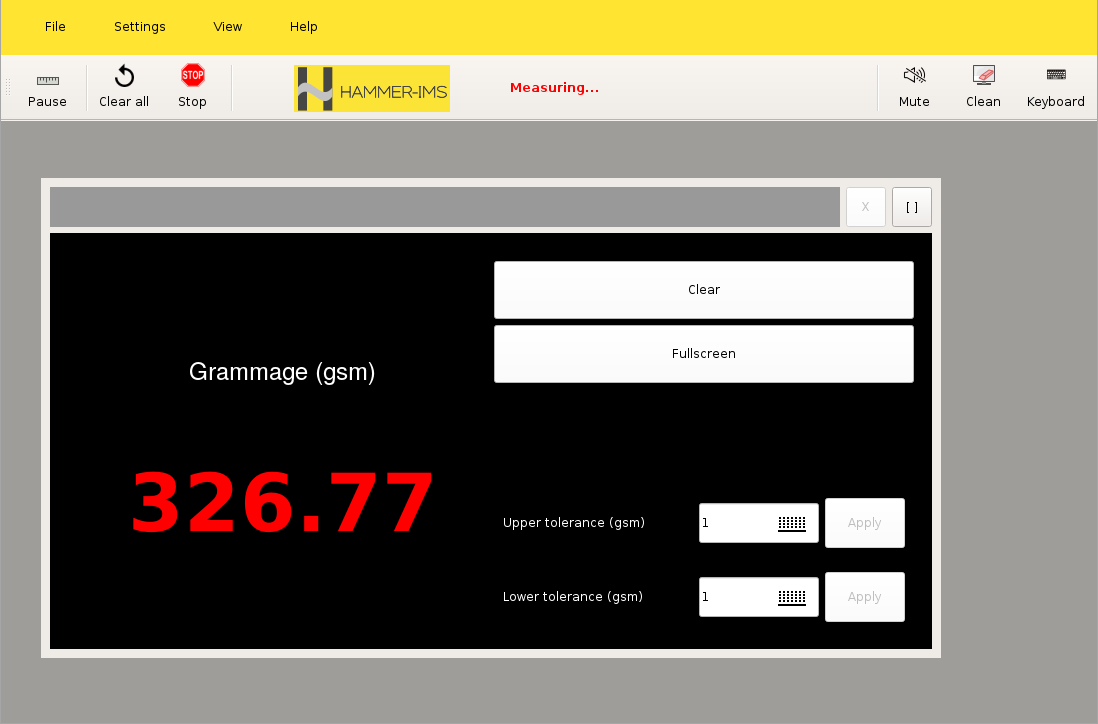

Our main software window only displays the features that really matter to our users. This is basically: a visualization (e.g. basis-weight as a numeric value), a Measure/Pause button, a Clear button and a Stop button. Furthermore, some buttons that are intended to make life easier: a Cleaning button (to disable the touch screen for 60 seconds to allow cleaning), a Keyboard button to show the touch keyboard and a Mute button to mute auditive alarms (e.g. a buzzer).

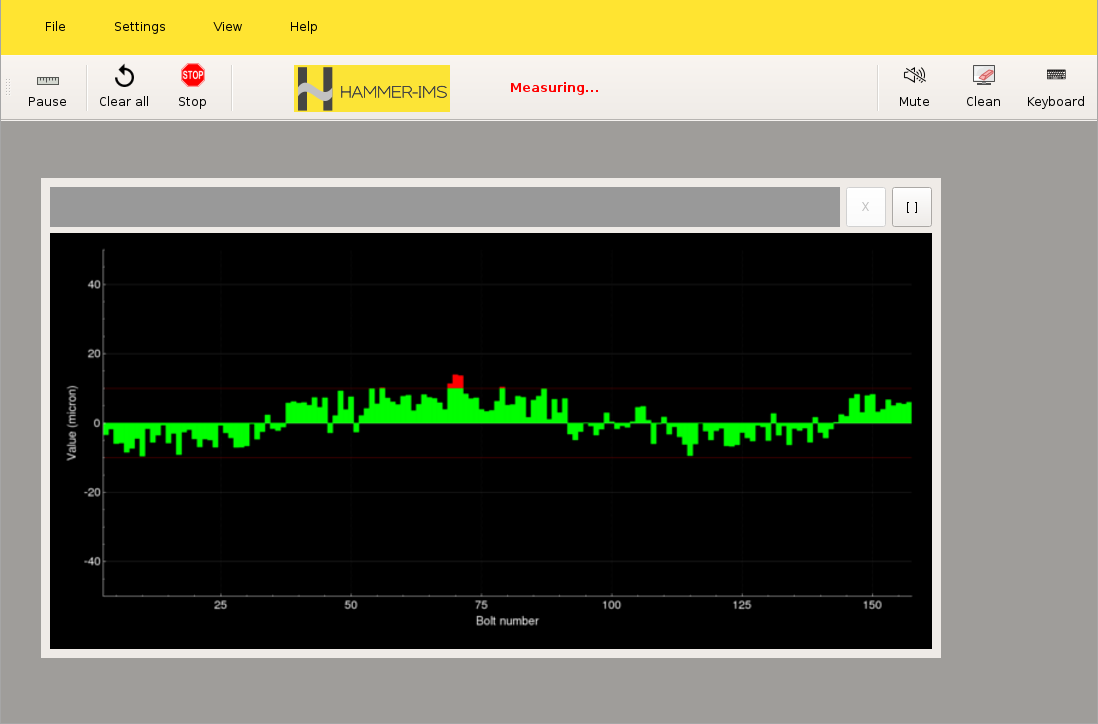

Industry-specific visualizations

The flexible design of the software enables us to deliver tailor-made visualizations for your industry. An installation on a plastic extrusion line would probably ask for a plugin showing the thickness for each tuning bolt, whereas a plastic calendering line does not deal with tuning bolts and therefore requires another plugin on its turn.

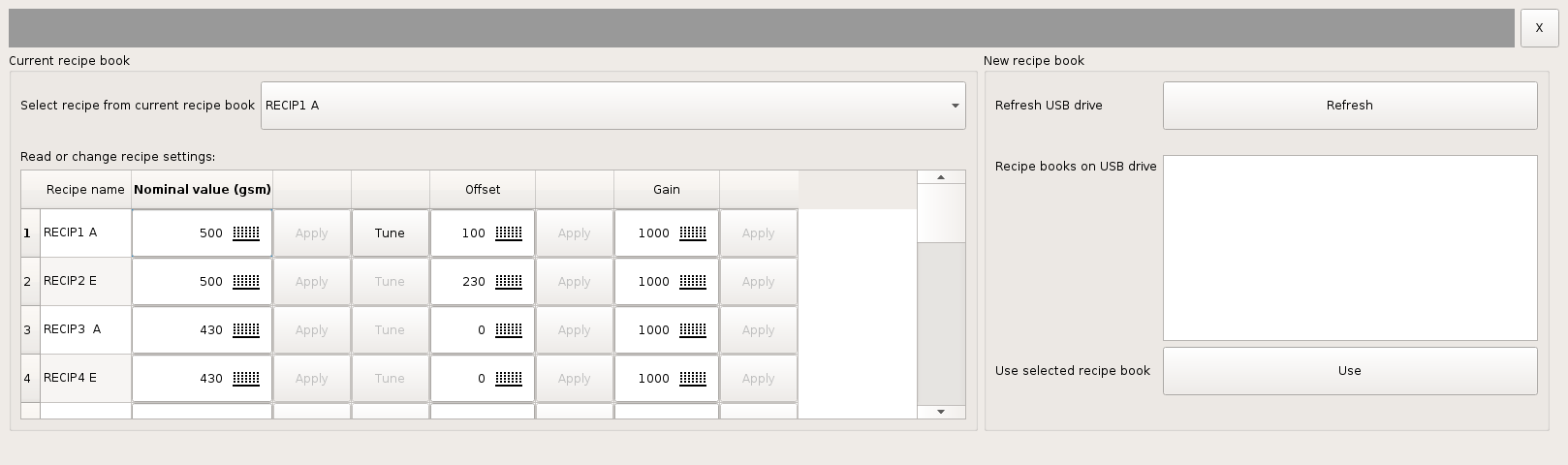

Built-in recipe selection

We do not need you to be an M-Ray professional to operate Hammer-IMS's measurement systems and Connectivity 3.0. The measurement system's configuration is pretty easy. We offer a single-click configuration of the software according to the recipe that is currently being processed/produced by your production equipment. Do not waste your precious time checking all configurations over and over again and do not let human mistakes or improper configurations be directly responsible for the quality of your products. Production managers can upload recipes from an Microsoft Excel-compatible file into Hammer-IMS's Connectivity software.

Data logging

The quality departement can obtain measurement data from our systems. Our rugged industrial computer platform has a front USB socket which can be configured for easy back up of any measurement data. This is practical for quality engineers to analyze measurement data in Microsoft Excel and draw conclusions about measurement data trends related to production quality and performance. Integrations with commercial database systems such as Microsoft SQL Server or data transfer over FTP or SFTP can also be enabled to customers and eliminate manual USB data transfers.

To further realize our Industry 4.0 vision, Hammer-IMS could, as an option, offer to bring measurement data to a secure spot in the cloud and in real time. New customers of Hammer-IMS can thus sign-up to see their industrial production data from anywhere in the world. The data is generated by Hammer-IMS systems which measure the thickness of plastic sheets or the basis-weight of fabrics, (technical) textiles and nonwovens. This feature is particularly useful for production managers, who want to share the well-structured data with stakeholders (colleagues, plant managers, C-level management, third party representatives, etc.) to optimize production batches.

The add-on feature allows for securely but restrictively sharing sensitive production information without getting trapped by strict firewall settings and restricted VPN tunnels. It reliably compresses and securely transfers the data between the Hammer-IMS scanners at customers' sites and the cloud infrastructure of Hammer-IMS. Also single-sheet pdf-reports (including key-performance indicators (KPIs)) can be extracted out of the stored measurement date from within the cloud, revealing key-performance indicators (KPI’s). The technology of OpenSSH technology is used for the point-to-point encryption and transmission of the sensitive data on a 24/7 basis. Resource scheduling ensures that the measurement machines remain fully responsive even when transmitting heavy loads of data to the cloud. The first commercial installation of the data logging in the cloud add-on in the summer of 2020. (Picture copyright Inmation Software GmbH)