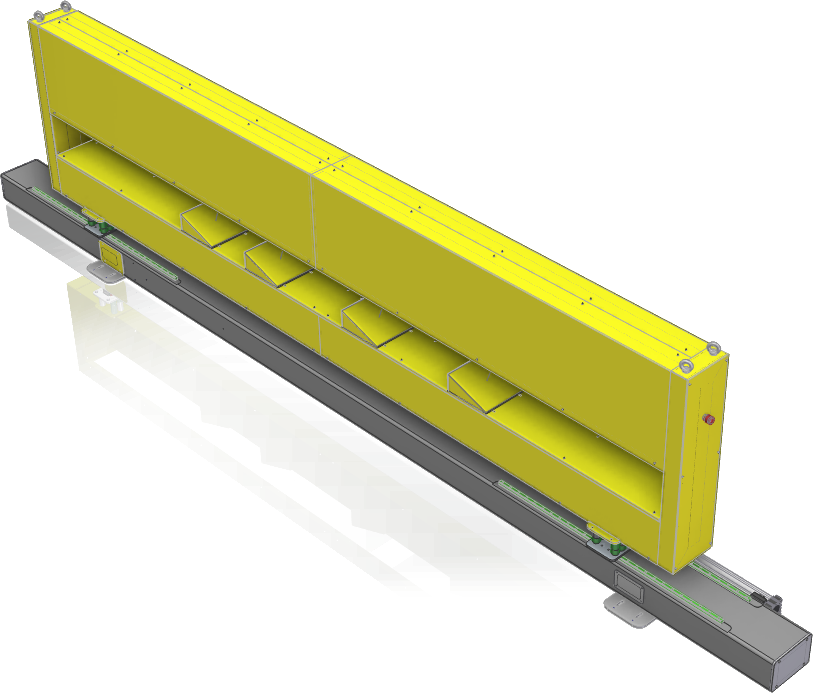

CURTAIN O-Frame

High-coverage inline thickness & basis-weight measurement

The CURTAIN O-Frame is a highly precise and robust inline measurement system designed for wide production lines. By supporting multiple sensor heads, it provides near-100% material coverage, ensuring accurate thickness and basis-weight measurement across the entire production width.

The CURTAIN O-Frame is highly flexible and can be equipped with:

- M-Ray technology

- L-Ray technology

- U-Ray technology

- Custom combinations

How does the CURTAIN O-Frame work?

The CURTAIN O-Frame moves along the production line, using multiple sensor heads to scan the entire width of the material. Unlike single-point scanning systems that miss sections of the material, the O-Frame’s multi-sensor design ensures continuous, high-precision measurements.

Why choose the CURTAIN O-Frame?

- Slim & Rigid Design – 300mm frame width for easier integration without compromising accuracy.

- Multi-Sensor Integration – Use M-Ray, L-Ray, U-Ray, or a combination for maximum flexibility.

- Fast Profile Measurements – Traveling O-Frame scans materials in real time.

- Safe & Efficient Technology – Non-nuclear, non-radioactive measurement options.

- Large Production Line Compatibility – Fits production lines up to 5+ meters wide.

Built-in Calibration for Accuracy

To maintain long-term measurement reliability, the CURTAIN O-Frame features automatic calibration to compensate for environmental changes.

How Calibration Works:

- The system calibrates itself periodically to ensure precise measurements.

- Calibration is performed either in air or using a reference material.