Our Marveloc-CIRCLE uses our Next-generation M-Ray technology to provide pipe-extruders a fast and accurate view on their production quality. Our Next-generation M-Ray technology applies radar in a 360-degrees setup to extract KPI's on the pipe's symmetry and sagging condition. The system matches with any extruded (non-corrugated) synthetical pipe technology: PP, PE, PVC or PPR.

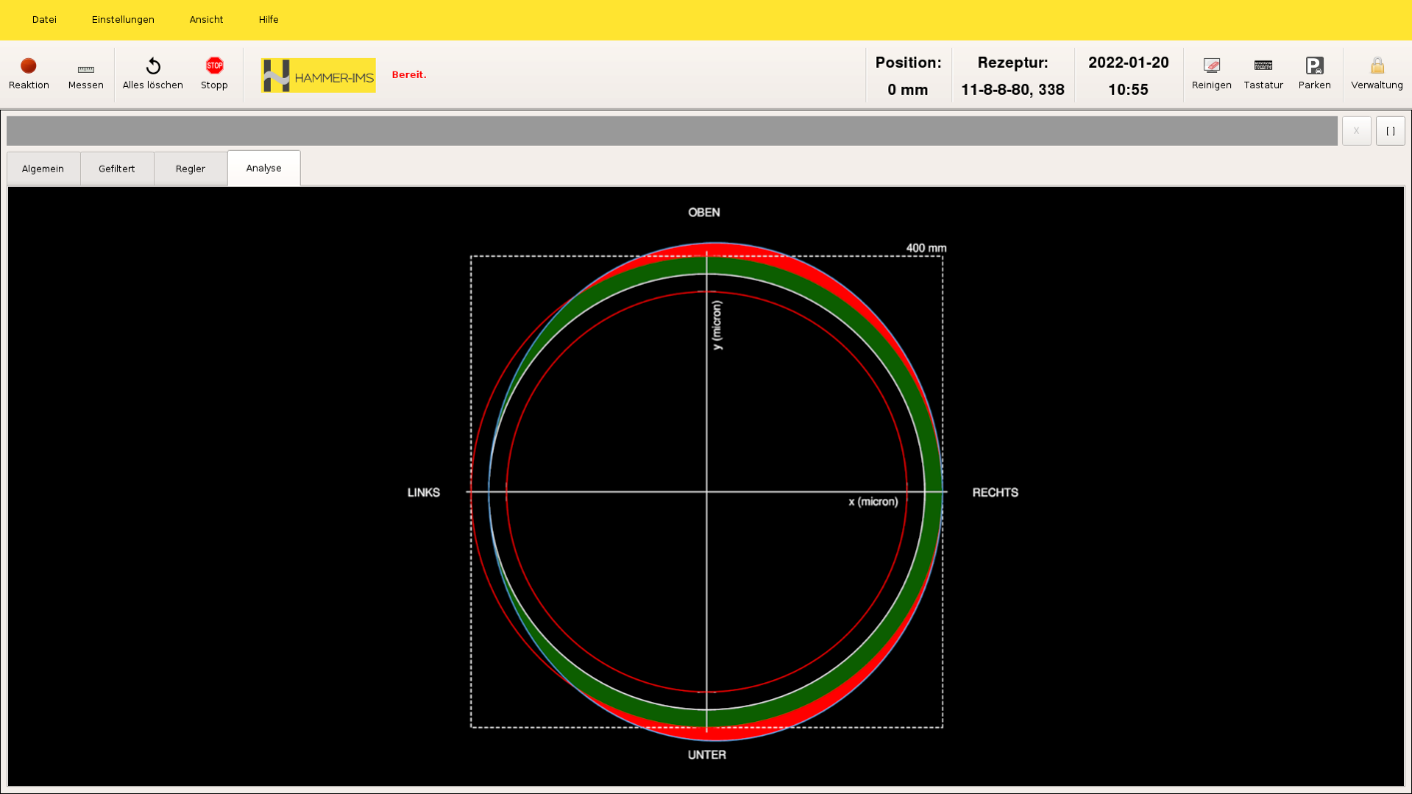

Connectivity 3.0, our software-experience for any of our measuring or machine-vision systems provides the right visualizations for both operators and quality personnel. 360-degrees pipe wall-thickness information is displayed in circular plots (polar plots), using intuitive coloring conventions to warn operators on whether production margins are being satisfied or not.

The Marveloc-CIRCLE provides a dual value proposition to the customer. The operators will deal with real-time visualizations on the screen, whereas quality personnel is able to analyze historical measurement data. For the latter, the Marveloc-CIRCLE system provides options for field-bus integrations over OPC UA, PROFINET, Modbus TCP, Microsoft SQL, or simple usb-stick-based data logging. Our engineers are open to help you creating your own data-processing scripts and algorithms in Microsoft Excel or alike.

During the commissioning phase of all types of measuring systems of the Marveloc-brand, we always send one of our own project or R&D engineers on site. We configure the system in such a way it works hand-in-hand with the existing equipment present at the customer's premises, furthermore, giving the right look and feel in the software. Important here is to optimize the trade-off response-time versus accuracy in the sweet spot and to make sure any connection to remote plc systems and databases are working as desired.