News

We happily returned from the international INDEX Nonwovens expo in Geneva, Switzerland. After exhibiting in China last June, we demonstrated our sustainable measuring and machine vision solutions. Visitors watched various demos that nicely illustrate our one-stop-shop for safeguarding qualitative manufacturing. It was great to see some of you again in person and discuss your specific quality control applications

'Hammer-IMS Internship Fellow' certificate for recent graduates sets a new tone in the Flemish job market. When Hammer-IMS settled on the Corda technology campus in Hasselt in 2016, founders Noël Deferm and Tom Redant had no idea that five years later, they would be shipping a large yellow machine to all corners of the world every month. "Our bright yellow color is our trademark," says Hammer-IMS. "In recent years, we have seen our company evolve from developing a single technical component to full-fledged machines. Large international textile and plastic groups view our products with great interest and often choose our machines over those of established German companies. Our cocktail of technological passion and staying grounded in the market is essential for entering a market and increasing our share. We want to pass this on to new young professionals."

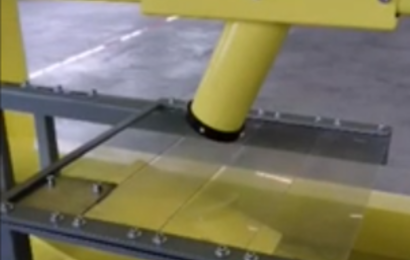

Watch our latest dual scanning system, which serves as an inline project for PMC felts at Heimbach Group (Olten, Switzerland). The automated M-Ray based system for grammage quality control eliminates radioactive sources at what the customer calls the pre-needle loom. We collaborated with Vansichen Linear Technology to fit a nearly 9 meters long steel linear module into a very limited inclined space envelope.

A few months ago Joost Poelmans joined the Hammer-IMS team as R&D engineer. Say hello to Joost who studied engineering and collaborates on pushing the non-nuclear M-Ray weight and thickness measuring technology. He also introduces intelligent machine vision to further increase the quality control experience for plastic, textile and nonwoven manufacturers.

For the first time, Hammer-IMS exhibits on the ITMA ASIA expo in Shanghai, China. This milestone event is China's most important textile event. "We are here to further extend our geographical reach and explore the huge Chinese market," says Tom Redant, CTO of Hammer-IMS. "We were able to scale geographically thanks to our non-nuclear M-Ray based systems for thickness and grammage measurement. Just recently, Hammer-IMS was awarded the VOKA Limburg export prize in Belgium. “We were able to scale geographically thanks to our non-nuclear M-Ray based systems for thickness and grammage measurement."

Read and watch the testimonial of one of our latest student interns. Are you a maker? apply: internships@hammer-ims.com

Over the last months we have been working on enhancing our products with advanced machine-vision techniques and abilities for remote control by means of an own Android-app. Check out the videos.

We are offering machine-vision solutions nowadays for the markets of textiles, nonwovens and plastics!

We apply 4k-camera technology for detection of anomalies and patterns in inline production environments. Check-out our website www.hammer-ims.com on our Edge-Vision-4.0 product line. Edge-Vision-4.0 is an additional eye to your product quality. It can be combined with our Marveloc technology for thickness and weight measuring to realize a full-blown quality-monitoring solution.

VOKA Limburg, a provincial section of the Flemish network of companies, awarded Hammer-IMS the 'Young Export Potential' prize. Hammer-IMS wins the prize in the category of promising companies, which resolutely opt for export to drive business growth.

With many international system installations taking place, we want to point out that the design, delivery and installation process of your order is in good hands. Your purchase with Hammer-IMS is a smart move, not only while we are working to deliver your shiny yellow machine on time but also when the machine will be running at your facility in your production line of choice.

Known for the world's most advanced fabric technologies, Low & Bonar creates versatile materials in smart combinations to deliver performance. Since May 2020 part of German Freudenberg Performance Materials, Low & Bonar Hückelhoven is a pioneer in the technical textiles group. "The first purchased installation within the Low & Bonar has been running now for more than 10 months here in Hückelhoven, Germany," says Plant Manager Henk Hoekstra.