News

Here's the OEM module of Hammer-IMS, ready to integrate into a variety of applications. It contains a 'millimeter wave' based sensor for material characterization as well as for distance measurements, vibration analysis and general detection cases. The compact module is packaged as a rugged, stainless steel box. It's rock solid and water resistant in order to operate on a 24/7 basis and to withstand harsh industrial environments. The OEM module comes with embedded software and API description for easy integration.

The theme of ‘entrepreneurship’ receives a lot of attention within the Faculty of Engineering at KU Leuven. An example of this is the spin-off company Hammer-IMS, which applies knowledge of mm-wave circuits to industrial applications. The powerful multi-sensor systems provide manufacturers of fabrics, plastics, and nonwovens with clear insight into the quality of their products. These innovative solutions serve as an alternative to existing nuclear and radioactive systems in the market.

This month three students, Tibo Meynckens, Stef Lenaerts and Yannick Geukens, finished their internships with us at Hammer-IMS.

Due to the covid-19 pandemic, most international expos of 2020 are canceled or postponed. Therefore, we are setting up a new lineup of events for 2021 to be able to meet you in person and discuss your specific QC applications.

Our disruptive M-Ray technology is pure electronic by nature. This means that our non-nuclear measuring solutions are harmless for people and the environment. Completely safe for operators...

Started in January this year, Dirk Irle joined Hammer-IMS as a seasoned sales and business developer in the DACH region, Eastern Europe and Scandinavia. He has over 30 years experience in sales, marketing and technical support positions for a range of solution providers in measurement and engineering. Dirk has an engineering degree in computer science.

Watch the interview video with plant manager Geert Veranneman of Grandeco Wallfashion Group in Tielt, Belgium. Furthermore, discover how such a system is integrated in a wallpaper production line.

Do you want to load external content supplied by Youtube?

Bringing industrial data safely and in real-time to remote IT infrastructures has always been challenging when working with classical technologies

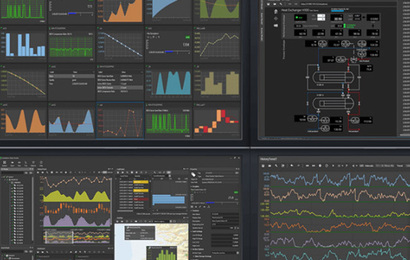

We have published a new video on our machine's user software's features.

Orfit Industries executes extrusion quality control of engineered thermoplastic sheets with inline Hammer-IMS measuring system.

The innovative thickness measuring system of Hammer-IMS is exactly what Orfit Industries in Antwerp needs for its high-temperature thermoplastic extrusion line. Medical specialists worldwide use Orfit’s thermoplastic sheets for orthotic and prosthetic purposes.