Every now and then, we give the word to one of our colleagues at Hammer-IMS. Today, Nele Reynders, Senior R&D Engineer, comments on the latest in measuring machine construction and measurement system integration.

How would you describe the engineering activities of your team within Hammer-IMS?

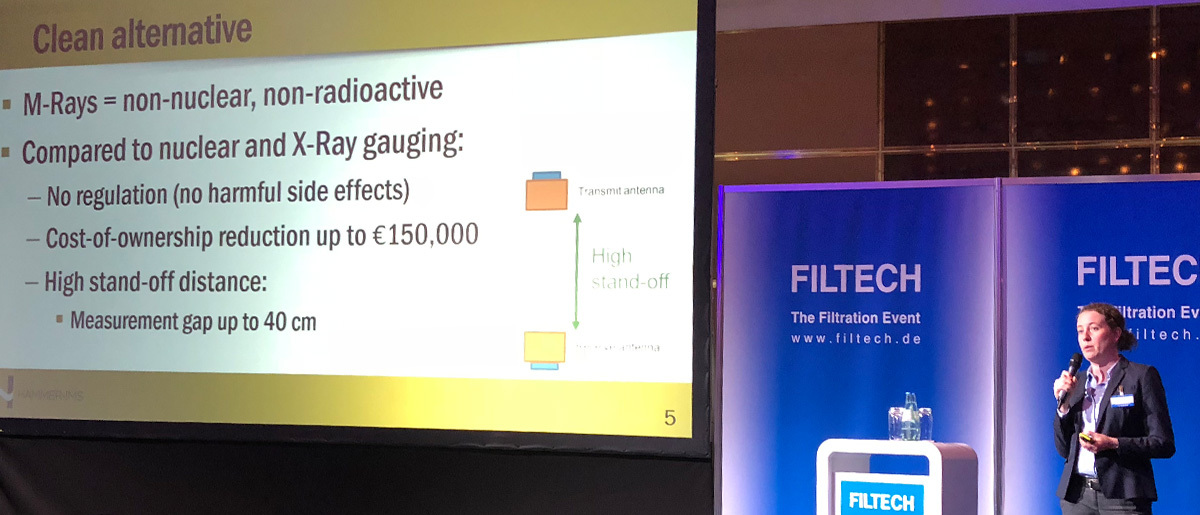

Mainly we focus on new developments in the three fields of mechanics, software and sensor integration. Firstly, the mechanical part has a strong emphasis on optimizing the metal machine O-frames and C-frames for high mechanical rigidity to facilitate accurate basis-weight or thickness measurements. It is a common misconception that a good sensor always leads to a good measuring system. Therefore, mechanical design should be handled with care. We are also developing some specialty machine configurations, e.g. a linear scanning drive mounted sideways instead of underneath the machine. Secondly, optimizing software that forms the layer between the machine and the customer has a strong position in our engineering activities. Lastly, we collaborate closely with our colleagues who develop the M-Ray sensors in support of flexible sensor integration. Overall, we have taken on a development approach that only requires minor development adaptations to meet most customer requirements.

Years ago you decided to put your shoulders under Hammer-IMS and outlined the way projects are being executed. How did that go?

From the beginning, we took customer feedback very seriously while executing the projects. In fact, the first customer projects were still developments and were difficult to be planned because of the trial and error approach and the uncertainty how the technology would react in certain inline cases. Back-then I co-developed these machines together with Tom and Noël, the founders of Hammer-IMS. During these projects we have picked up the skills of building machine frames that accommodate flexibility in machine width and number of sensor heads. The initial projects provided us a lot of information which we would use to create a formal project flow, while still allowing to provide the customer with an on-request machine width or number of sensor heads. Proposing the right solution for the customer that fits the tight inline specifications while keeping delivery times short is really the strength of the way projects are being executed at Hammer-IMS.

How do you put in practice project management and internal documentation?

A structured approach is essential in setting up a performant and agile team. Defining work schedules with regular follow-up meetings enables the team members to execute projects better and faster. Important in this regard is consistency in documentation, which allows new engineers and interns to get up to speed faster. Our team is using professional future-proof tools and systematically evaluates and optimizes our engineering processes. Along the way, we accurately keep track of our stock of components and carefully select our suppliers. We prefer a limited number of suppliers who are flexible, think along with us, and support us properly. Also, we are adopting a deeper level of engineering by taking in more development work in-house.

What technical developments make your heart tick faster?

The new-generation of CURTAIN C-frame machines was a challenging achievement. The detailed development of the machine and measurement control was quite interesting and fun at the same time. By engineering hardware and software feedback loops, our solutions can flexibly communicate with existing production line management systems on customer sites. I like the variety of engineering tasks. On the software site, we are developing new features that further facilitate machine installation and operation. Also, we increasingly execute sensor integration work to have M-Ray and other sensor types operate alongside in our machines to perform quality control on multiple levels.