Geosynthetics

Quality measurement for all geosynthetic applications

In the production of geosynthetics, precision and uniformity are essential to meet industry specifications and ensure reliable performance across applications like soil reinforcement, erosion control, and drainage systems. Our advanced non-contact measurement technologies help you to achieve unmatched quality and efficiency throughout the production of geotextiles, geogrids, geocells, geonets, geospacers, and geomats.

Geotextiles

Geotextiles are produced through processes such as weaving, knitting, or non-woven techniques like needling or heat bonding, followed by finishing treatments. During these stages, our systems can play a critical role:

- After the formation of the fabric, whether woven or non-woven, precise thickness and weight-per-unit-area measurement ensures uniformity and compliance with specifications.

- Additionally, during any coating or lamination steps, our solutions can monitor the uniformity of coatings in real-time, preventing material waste and ensuring high-quality finishes.

Geogrids

The production of geogrids involves the extrusion of polymer sheets, followed by stretching, perforating, and sometimes coating. This structured process benefits significantly from integrated monitoring systems:

- Post-extrusion monitoring ensures the polymer sheet maintains consistent thickness, a critical factor for the mechanical strength of the final geogrid.

- During the coating phase, our technology can measure the coating’s thickness and weight distribution, ensuring even application across the grid structure.

Geocells

Geocells are manufactured by welding strips of polymer (like HDPE) into a 3D honeycomb structure. The precision of this process impacts their load distribution capabilities.

- After the extrusion of polymer strips, our sensors can measure the strip thickness to maintain uniformity, ensuring consistent strength.

- During the welding stage, our technology can validate that the thickness of the bonded areas aligns with product requirements, avoiding weak points.

Geonets

Geonets are produced through an extrusion process that forms a net-like structure with interconnecting nodes and filaments. The consistent performance of geonets depends on uniform thickness and strength across the structure.

- Directly after extrusion, our sensors can ensure the thickness of the filaments and nodes meets design tolerances.

- In the final quality control stage, our systems can verify the uniformity of the geonet to ensure reliable performance in drainage or separation applications.

Geospacers

Geospacers are complex 3D structures used for drainage or separation, created through extrusion or bonding processes. Maintaining structural integrity is key:

- During the extrusion phase, our technology can measure the thickness of the polymer layers, ensuring they are uniform across the entire geospacer.

- If the process involves lamination or bonding, our sensors can provide real-time feedback on material weight and thickness, verifying that each layer is correctly bonded for optimal performance.

Geomats

Geomats are produced by entangling polymer fibers into a 3D matrix, often with heat bonding to stabilize the structure. These materials require precise control during production to maintain their erosion control and drainage properties.

- During the fiber entanglement phase, our systems can monitor thickness and uniformity, ensuring the 3D structure forms as designed.

- In the bonding stage, whether through heat or adhesive, real-time measurement ensures the geomat retains consistent thickness and basis weight, meeting performance specifications.

Products for this industry

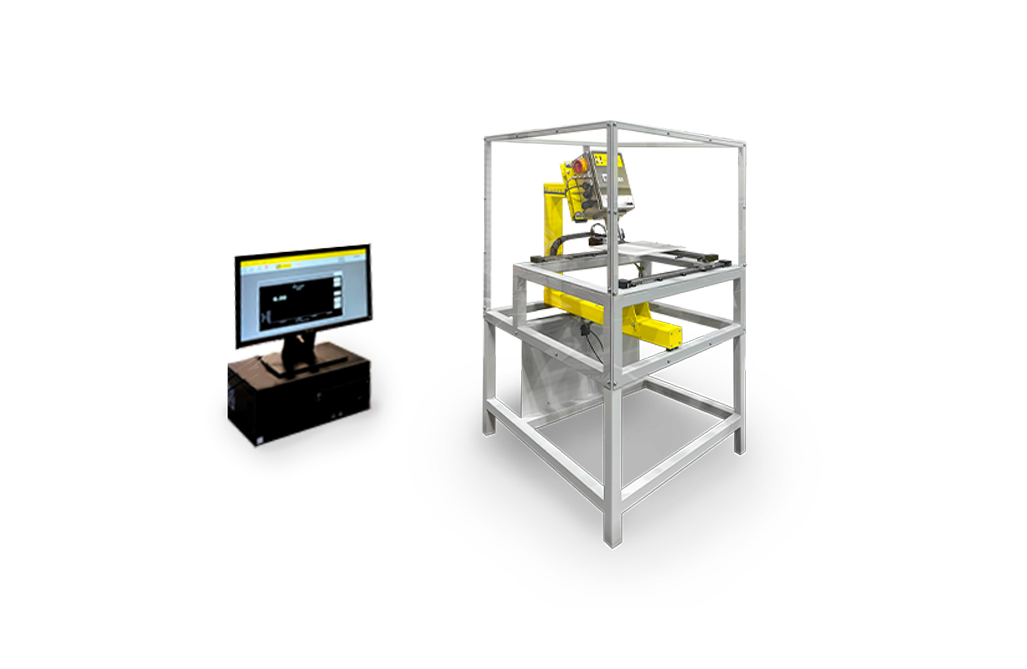

Marveloc-CURTAIN-O featuring M-Rays

Machine for basis-weight measurement of flat materials

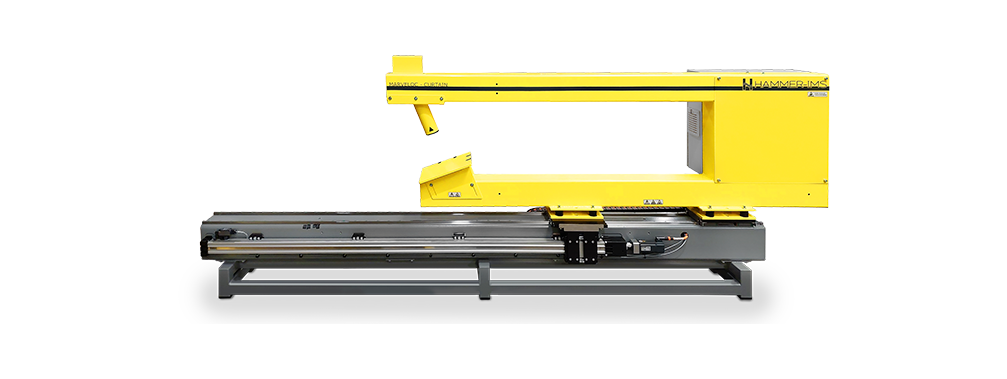

Marveloc-CURTAIN-C featuring M-Rays

Machine for basis-weight measurement of flat materials

Edge-Vision-4.0-CURTAIN-O featuring 4k multi-cam

Surface inspection solution for detection of anomalies and defects

Edge-Vision-4.0-CURTAIN-C featuring 4k multi-cam

Surface inspection solution for detection of anomalies and defects

M-Ray OEM Module featuring M-Rays

For OEM projects on basis-weight measuring by machine builders and sensor integrators

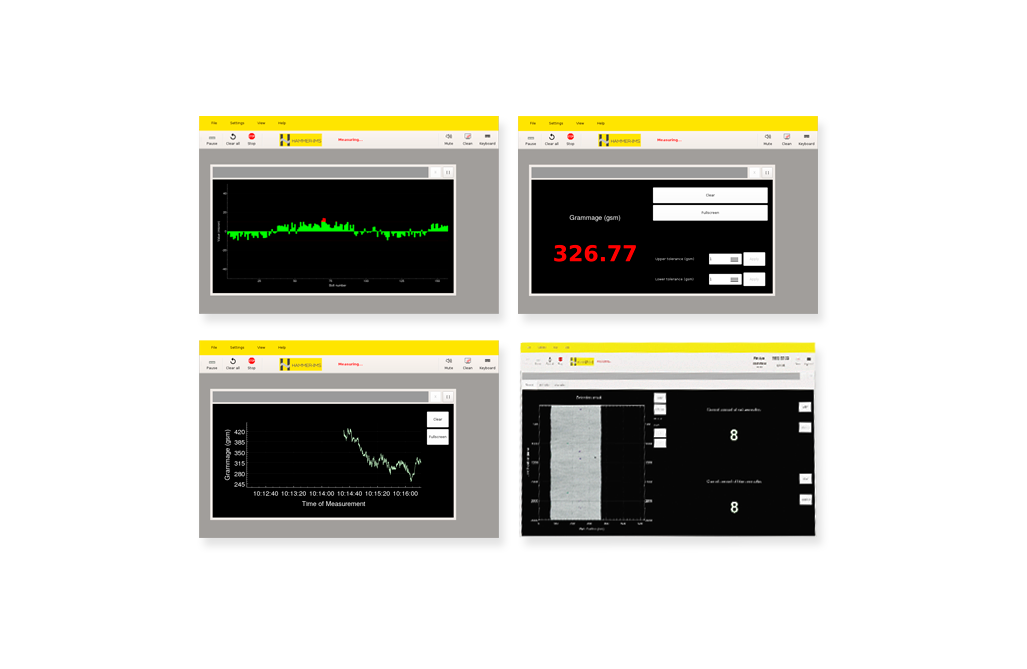

Connectivity 3.0

Industrial software to connect to PLC's and various information sources

Lab devices featuring Miscellaneous technologies

Lab devices, custom or off-the-shelf