Animal and bio-based leathers

Crafted from Nature

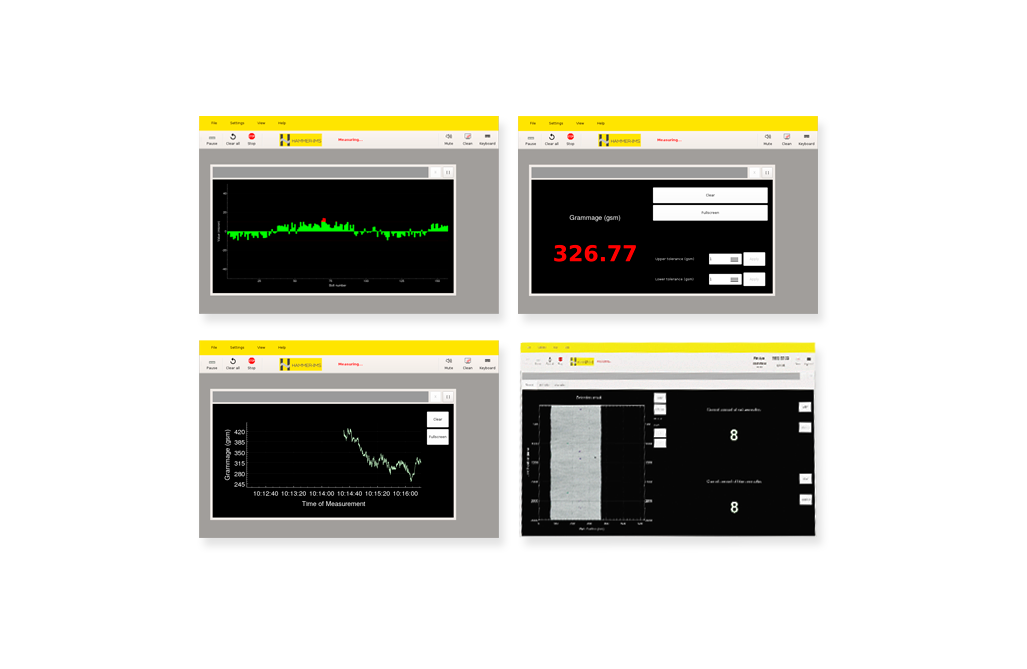

High-quality leather, whether traditional or bio-based, starts with accurate measurements. Our advanced, non-contact measurement solutions help you control thickness, density, and texture, which are essential for ensuring consistency and promoting sustainability. This precision is key to maintaining product standards and reducing waste, especially with the natural variability of bio-based leathers.

Applications across a range of leather types

Traditional leather

During the tanning and finishing stages, our systems are ideal for precise control of thickness and texture, ensuring uniform quality and optimal processing of animal hides.

Mycelium leather

In the drying and finishing phases, we ensure consistent density and thickness, crucial for the durability and aesthetics of the final product.

Pineapple leather

Our solutions assist in the fiber processing stage, where even fiber distribution and thickness control are essential to minimize waste and enhance consistency.

Apple leather

In the pressing and lamination step, we provide precision in density and thickness regulation, resulting in a perfectly finished product that is both flexible and durable.

Products for this industry

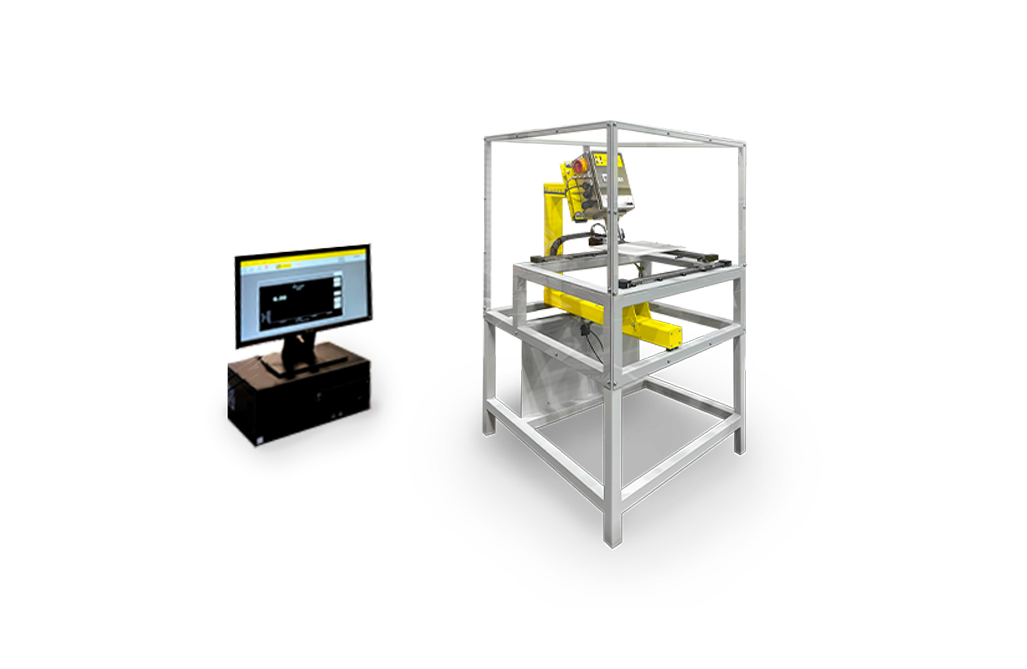

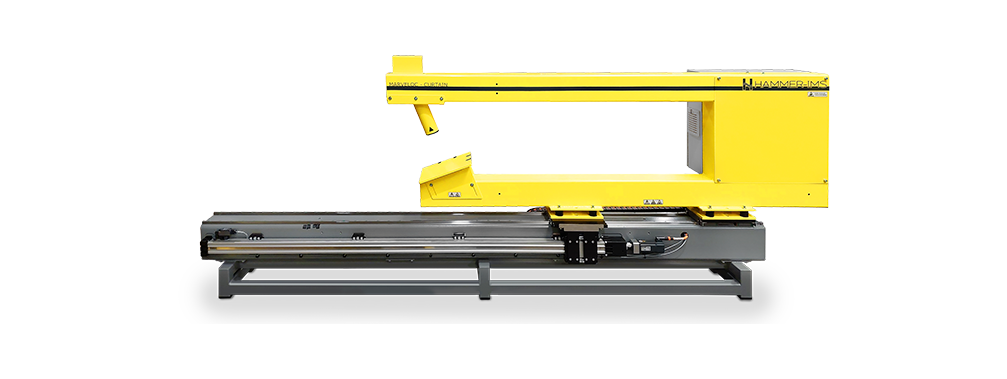

Marveloc-CURTAIN-O featuring M-Rays

Machine for basis-weight measurement of flat materials

Marveloc-CURTAIN-C featuring M-Rays

Machine for basis-weight measurement of flat materials

Edge-Vision-4.0-CURTAIN-O featuring 4k multi-cam

Surface inspection solution for detection of anomalies and defects

Edge-Vision-4.0-CURTAIN-C featuring 4k multi-cam

Surface inspection solution for detection of anomalies and defects

M-Ray OEM Module featuring M-Rays

For OEM projects on basis-weight measuring by machine builders and sensor integrators

Connectivity 3.0

Industrial software to connect to PLC's and various information sources

Lab devices featuring Miscellaneous technologies

Lab devices, custom or off-the-shelf