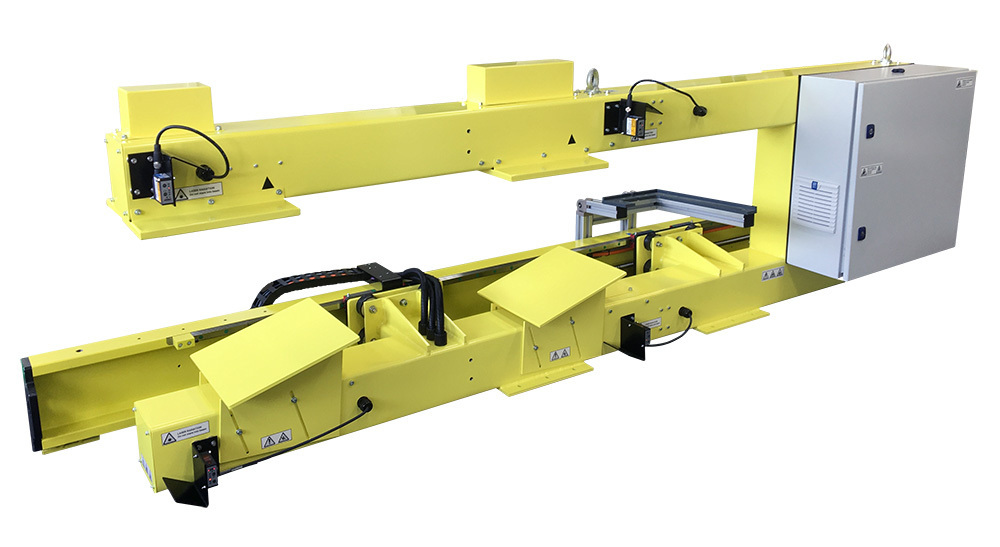

Marveloc-CHARIOT systems accommodate a single sensor of any type. Marveloc-CURTAIN systems accommodate a single sensor or multiple sensors possibly combining various sensor types of Hammer-IMS or third parties:

Sensor fusion supports a vast choice of sensors and allows different types of sensors to be installed in your Marveloc-CURTAIN system in order to execute different measurements simultaneously. Concretely, Hammer-IMS offers sensor technologies for thickness, basis-weight and other measurements in a single non-contact measuring solution. We see that simultaneously measuring material thickness and basis-weight is emerging nonwovens quality control.

The combined thickness/weight measuring solution of Hammer-IMS perfectly responds to this market evolution. In a typical setup, a non-nuclear M-Ray sensor measures nonwoven basis-weight while a laser sensor continually tracks the material thickness. In addition, the laser sensor continuously identifies the edge of the moving nonwoven produce using enhanced-precision material edge detection. For optimal operation, the laser sensor requires sufficient material reflectivity.

Another reason to add a laser sensor is obtaining the same high precision regardless when gauging thin or thick materials inline. Sensor fusion creates an optimal tradeoff between precision and measurement range in any Hammer-IMS thickness of basis-weight measuring solution.

There are many sensor types that can be combined in Hammer-IMS measuring systems, ranging from multiple laser types to Eddy Current sensors. Hammer-IMS has the hardware and software expertise to integrate various sensor types into its gauging machines. Contact Hammer-IMS to discuss your specific measuring application.