Discover the accuracy and precision of Hammer-IMS' 2D Scanner Demo Machine and its exceptional performance at various industry fairs. Visitors at ITMA Milan 2023 were able to experience firsthand the cutting-edge technology that has revolutionized quality control processes across multiple sectors. The revolutionary 2D-scanner is designed for unparalleled 100% inspection and measurement of basis-weights.

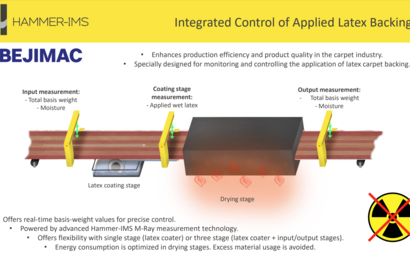

Bilateral international agreement signed for coating grammage improvement in finishing lines for woven, tufted and needle-punched carpets and artificial grass.

Vandewiele's daughter company Bejimac, specialist in textile finishing machines, established a structural collaboration with Hammer-IMS on quality control of latex coating. This agreement fits in the shared vision of Vandewiele, Bejimac and Hammer-IMS to digitalize the finishing lines for carpets in which accurate, adaptive measurement plays an essential role. Hammer-IMS dedicatedly integrates its non-nuclear technology for measuring coating grammage into Vandewiele-Bejimac finishing lines. Thanks to the real-time measurement and automatic system adaptation of these smart systems, carpet manufacturers maintain highest product quality while reducing the usage and scrap of expensive latex material. The collaboration agreement stipulates that Vandewiele sells and distributes its Hammer-IMS enabled finishing lines. This resellership covers the entire world, except EU, the United Kingdom, Norway and Switzerland.

Fruitful collaboration with metalworking company in Hasselt results in robust and accurate mechanical structures with sleek yellow finishing for a worldwide export market

Abriso-Jiffy is a pioneer in producing in an environmentally friendly way with an inline quality control system from Hammer-IMS.

Read their Testimonial here

Watch our latest dual scanning system, which serves as an inline project for PMC felts at Heimbach Group (Olten, Switzerland). The automated M-Ray based system for grammage quality control eliminates radioactive sources at what the customer calls the pre-needle loom. We collaborated with Vansichen Linear Technology to fit a nearly 9 meters long steel linear module into a very limited inclined space envelope.

DILO - a leading German producer of fully-integrated nonwoven production lines - will showcase a system of Hammer-IMS on ITMA 2019.

ANL Plastics – an internationally renowned producer of thermoformed plastic packaging – is now using equipment from Hammer-IMS in its production facilities in Wellen, Belgium. Hammer-IMS, a joint start-up from KU Leuven University Belgium and LRM Belgium, recently delivered its Marveloc-CURTAIN measurement system to the packaging producer. The system contains four M-Ray sensors, continuously measuring the plastic thickness on an ANL Plastics production machine. ANL Plastics experiences the technology of Hammer-IMS as fast, robust, secure, ecologic and easy-to-install. The technology is considered as a potential game-changer for the plastic packaging market, since Hammer-IMS products do not use nuclear energy.