ANL Plastics – an internationally renowned producer of thermoformed plastic packaging – is now using equipment from Hammer-IMS in its production facilities in Wellen, Belgium. Hammer-IMS, a joint start-up from KU Leuven University Belgium and LRM Belgium, recently delivered its Marveloc-CURTAIN measurement system to the packaging producer. The system contains four M-Ray sensors, continuously measuring the plastic thickness on an ANL Plastics production machine. ANL Plastics experiences the technology of Hammer-IMS as fast, robust, secure, ecologic and easy-to-install. The technology is considered as a potential game-changer for the plastic packaging market, since Hammer-IMS products do not use nuclear energy.

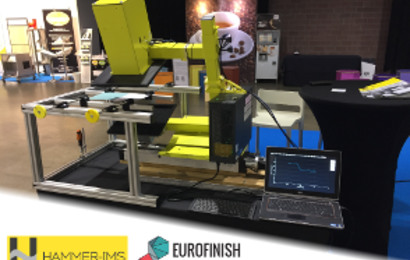

Hammer-IMS shows a contactless coating thickness measurement at Eurofinish in Haasrode Belgium the coming days. Our CURTAIN-demo setup shows how we can provide clean solutions for contactless coating thickness measurement, e.g. for textile coatings. Come and discuss your project with us even it requires ATEX certification. www.eurofinish.be.

Hammer-IMS exhibits on INDEX 2017 in Geneva, the world’s premier nonwoven industry trade fair. After successful intro in plastics industry, Marveloc-CURTAIN multi-head solution innovates inline measurements of nonwovens in automotive & building construction.

The next major event where Hammer-IMS will exhibit is the INDEX trade show in Geneva, Switzerland. Come to this leading nonwovens exhibition, and check out our M-Ray based inline measuring products.

Plastics Machinery Magazine (US) published Hammer-IMS CURTAIN solution in special report on innovative ‘multi’ units for film thickness testing. Among suppliers of film inspection equipment, “multi” is the latest buzzword. At the K show in Düsseldorf, Hammer-IMS introduced its CURTAIN multisensor device for measuring thickness.

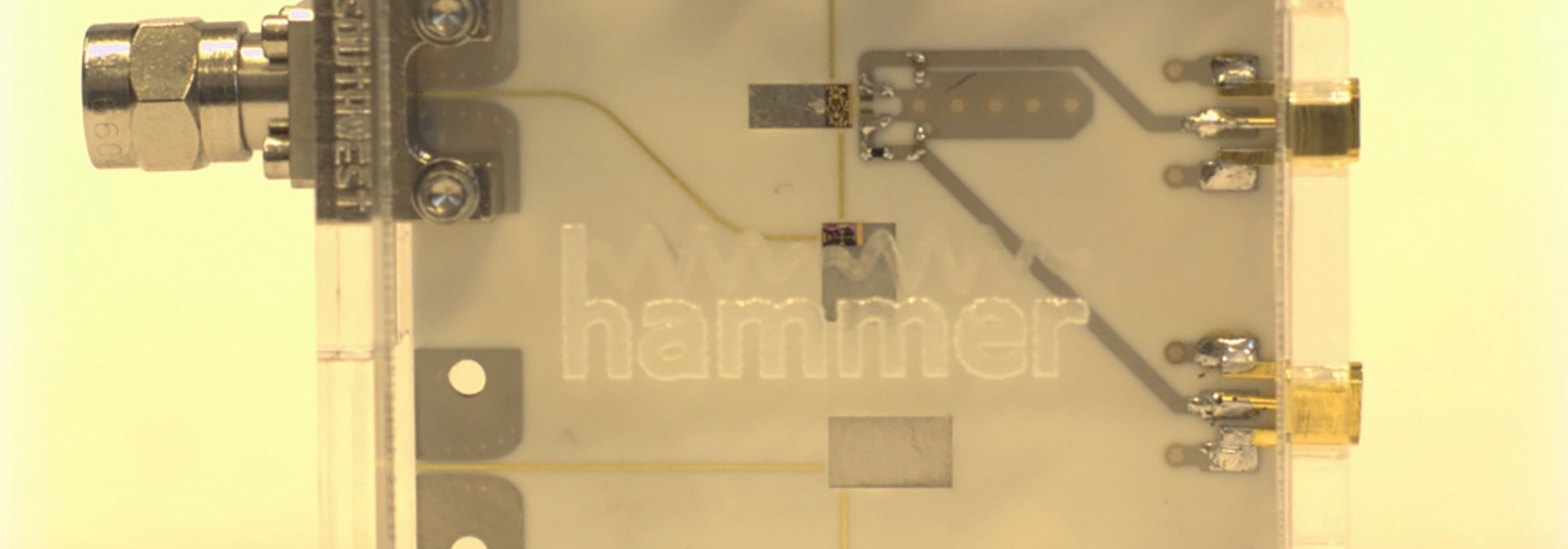

Only eight months after its incorporation and investment capital round, Hammer-IMS exhibits on K-Messe, the world’s premier plastics industry trade fair in Düsseldorf. At this occasion, Hammer-IMS of Flanders demonstrates its new turnkey CURTAIN multi-head solution for measuring thickness and weight in production lines. Co-founders Noël Deferm and Tom Redant of the KU Leuven spin-off company developed a complete portfolio of revolutionary measuring solutions based on ‘M-Rays’ – electromagnetic millimeter waves. The turnkey systems have been performing trial runs at international paper producers and manufacturers of plastic sheets and films, composites and many other materials. Hammer-IMS offers a secure, ecologic and easy-to-install alternative for today’s nuclear measuring equipment. Come and watch the Hammer-IMS system in action on K-Messe – Hall 11 Booth E64.

Our Hammer-IMS innovation has been accepted in the ‘Hall of Fame’ of Kunststoffen 2016 in Veldhoven, Netherlands. Come and watch this innovation, and visit the Hammer-IMS stand.

Hammer-IMS is a Belgian high-tech company in the field of industrial sensing. Hammer-IMS supplies highly accurate and contactless measurement systems based on the disruptive technology of millimeter waves. Hammer-IMS is now setting up partnerships with resellers in order to support its international expansion.

Based on millimeter waves, Hammer-IMS developed new systems for measuring thickness and weight in production lines of sheets and films. This innovative electromagnetic technology is seen as a powerful alternative for today’s nuclear measuring equipment, which governments want to gradually ban. Furthermore the technology offers up to micron level accuracy on industrial production floors, measuring both transparent and opaque in any color as well as rough & shiny surfaces.

(English language) The ambitions of the two engineers-entrepreneurs Noël Deferm and Tom Redant of start-up Hammer-IMS are (rightly) big: '"We want to make our non-nuclear millimeter waves based technology the golden standard in our application domains. The market is ready, because "Europe discourages the use of today's nuclear measuring equipment".

Corda Campus Hasselt – On June 10, Hammer-IMS welcomed around 70 guests in the PhiliCorda room to celebrate the launch of the new spin-off. During the event, Noël Deferm (general manager) and Tom Redant (technical & product manager) unveiled their plans for their non-nuclear Marveloc measurement technology, which is based on millimeter waves. Following their presentation, Professor Patrick Reynaert (KU Leuven), Kurt Hensen (CEO of T&M Solutions, now Averna), and Lieven De Jonge (Head of Smart Manufacturing, LRM) addressed the attendees. Both founders developed new systems for measuring thickness and weight in production lines, which are currently being tested by international producers of paper, plastic sheets and films, composites, textiles, glass wool, and other materials.