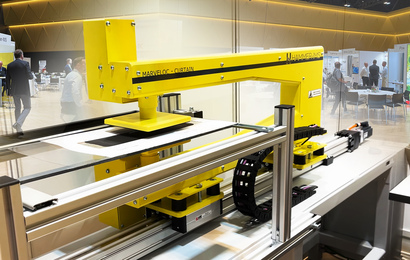

Hammer-IMS is proud to showcase its Marveloc-CURTAIN-MINI at the 13th European Advanced Automotive Battery Conference (AABC 2023) with a combination of U-Ray and L-Ray sensors that together perform thickness and basis weight measurements of battery film electrode coating and cell calendering stages.

After INDEX in Geneva last November, Hammer-IMS resumed its exhibition tour across Germany in Winter & Spring 2022. Many people came and visited us to watch one of our non-nuclear inline thickness and basis weight measuring systems in action! For example, the sleek and slim C-frame based system proves to be ideal for quality control of foils and films as well as coatings, paper, fabrics, textiles and nonwovens.

Hammer-IMS has participated in a range of events in Rome, Chemnitz and Cologne.

Hammer-IMS kindly invites you to the upcoming Belgian event (co-organized by Hammer-IMS) where Technical and Product Manager Tom Redant will speak. The event includes short presentations related to innovative measuring techniques for coatings and a visit of the Hammer-IMS facilities.

Plastics Machinery Magazine (US) published Hammer-IMS CURTAIN solution in special report on innovative ‘multi’ units for film thickness testing. Among suppliers of film inspection equipment, “multi” is the latest buzzword. At the K show in Düsseldorf, Hammer-IMS introduced its CURTAIN multisensor device for measuring thickness.

Based on millimeter waves, Hammer-IMS developed new systems for measuring thickness and weight in production lines of sheets and films. This innovative electromagnetic technology is seen as a powerful alternative for today’s nuclear measuring equipment, which governments want to gradually ban. Furthermore the technology offers up to micron level accuracy on industrial production floors, measuring both transparent and opaque in any color as well as rough & shiny surfaces.