News

The theme of ‘entrepreneurship’ receives a lot of attention within the Faculty of Engineering at KU Leuven. An example of this is the spin-off company Hammer-IMS, which applies knowledge of mm-wave circuits to industrial applications. The powerful multi-sensor systems provide manufacturers of fabrics, plastics, and nonwovens with clear insight into the quality of their products. These innovative solutions serve as an alternative to existing nuclear and radioactive systems in the market.

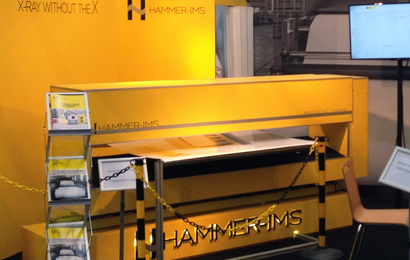

Plastics Machinery Magazine (US) published Hammer-IMS CURTAIN solution in special report on innovative ‘multi’ units for film thickness testing. Among suppliers of film inspection equipment, “multi” is the latest buzzword. At the K show in Düsseldorf, Hammer-IMS introduced its CURTAIN multisensor device for measuring thickness.

Only eight months after its incorporation and investment capital round, Hammer-IMS exhibits on K-Messe, the world’s premier plastics industry trade fair in Düsseldorf. At this occasion, Hammer-IMS of Flanders demonstrates its new turnkey CURTAIN multi-head solution for measuring thickness and weight in production lines. Co-founders Noël Deferm and Tom Redant of the KU Leuven spin-off company developed a complete portfolio of revolutionary measuring solutions based on ‘M-Rays’ – electromagnetic millimeter waves. The turnkey systems have been performing trial runs at international paper producers and manufacturers of plastic sheets and films, composites and many other materials. Hammer-IMS offers a secure, ecologic and easy-to-install alternative for today’s nuclear measuring equipment. Come and watch the Hammer-IMS system in action on K-Messe – Hall 11 Booth E64.

Hammer-IMS is a Belgian high-tech company in the field of industrial sensing. Hammer-IMS supplies highly accurate and contactless measurement systems based on the disruptive technology of millimeter waves. Hammer-IMS is now setting up partnerships with resellers in order to support its international expansion.

Based on millimeter waves, Hammer-IMS developed new systems for measuring thickness and weight in production lines of sheets and films. This innovative electromagnetic technology is seen as a powerful alternative for today’s nuclear measuring equipment, which governments want to gradually ban. Furthermore the technology offers up to micron level accuracy on industrial production floors, measuring both transparent and opaque in any color as well as rough & shiny surfaces.

(English language) The ambitions of the two engineers-entrepreneurs Noël Deferm and Tom Redant of start-up Hammer-IMS are (rightly) big: '"We want to make our non-nuclear millimeter waves based technology the golden standard in our application domains. The market is ready, because "Europe discourages the use of today's nuclear measuring equipment".

Hammer-IMS is a new spin-off from the internationally renowned research laboratory ESAT - MICAS of KU Leuven, and starts off with a capital injection of € 800.000. The investors are Gemma Frisius Fonds KU Leuven and Limburgse Investerings maatschappij (LRM). Both investment institutions gained years of experience in supporting high tech start-ups. After 8 years of research in the university, general manager Noël Deferm and technical & product manager Tom Redant started their company Hammer-IMS. Based on millimeter waves, Deferm and Redant developed new systems voor measuring thickness and weight in production lines. Their revolutionary measuring solutions are performing trial runs at international paper producers and manufacturers of plastic sheets and foils, composites, textile, glass wool and other materials. Hammer-IMS offers a powerful alternative for today’s nuclear measuring equipment, of which the usage is discouraged by the government. In short: performant industrial measuring solutions that are secure, ecologic and easy to install.